3 Dead and 1 Seriously Injured! An Accident Occurred in the Aerial Passenger Device of the Auxiliary Inclined Shaft of the Coal Mine.

At 14:19 on June 15th, Luliang, Shanxi, the auxiliary inclined shaft of China Coal Group had an overhead passenger device transportation accident.

.jpg)

After preliminary verification, the accident caused a total of 3 deaths, 1 serious injury and several minor injuries. The coal mine has been ordered to suspend production for rectification, and the aftermath disposal work has begun.

1. Equipment monitoring is urgent

Recent years, various mine accidents have caused huge losses to people's lives and property, and the situation of safety production is extremely severe.

All localities and mining enterprises must learn the lessons of the accident and take decisive measures to effectively prevent the occurrence of larger or more serious accidents.

2. The correct selection of equipment testing technology is needed

In the mine production work, the overhead passenger device is an important transportation device for the underground workers to go for work. In order to shorten the time of miners going up and down the shaft and reduce the physical exertion of miners going up and down the shaft, the overhead passenger device has become an indispensable equipment. Thus as an important part of overhead passenger device, the wire rope is significant for safe production.

3. How to ensure the safety of wire rope?

Non-destructive testing technology is a safety testing method commonly used in various industries.

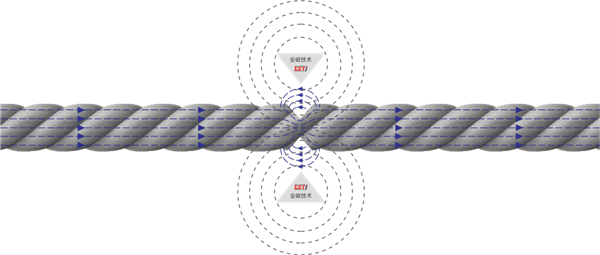

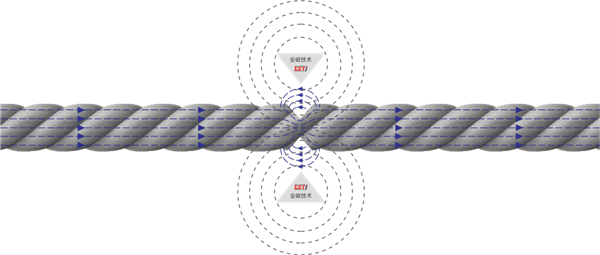

At present, Luoyang TST Flaw Detection Technology Co., Ltd. (hereinafter referred to as "TST") has "full magnetic detection" technology, which overcomes the safety management problem of non-destructive testing of ferromagnetic metal components (wire ropes). And professionally provides customers with non-destructive detection technology services for steel wire ropes , equipment sales and security management solutions.

TST overhead passenger device steel wire rope real-time online intelligent flaw detection system has been applied to many enterprises.

The system can monitor the safety of the steel wire rope throughout its life cycle, quantitatively detect various damages such as internal and external broken wires, abrasion, corrosion, and fatigue of the steel wire rope through NDT technology, and correctly evaluate the remaining bearing capacity and service life of the steel wire rope, provide users with inspection results that meet the requirements of standards.

It can be equipped with TST wire rope visual image flaw detection system to effectively and accurately detect different defects and damages of wire ropes, and enrich the detection results, which makes the test results more intuitive.

The application of TST series products can keep the steel wire rope in a safe and controlled detection state all the time, solve hidden dangers and ensure safe production. Promote the deep integration of safety management in smart construction sites, smart mines, and smart cities.

prev: TST Attended the 2023 Ship Industry Safety Production and Emergency Management Conference

next: Another Wire Rope Breakage Accident: 2 People Died

.jpg)