DeepSeek Empowers Wire Rope Inspection, Ushering in a "Digital and Intelligent Leap" for Wire Rope Safety Production!

With the rapid development of artificial intelligence (AI) technology, AI is gradually penetrating various industries, driving industrial upgrades and innovation. Luoyang TST Inspection Technology Co., Ltd. has seized this trend by focusing on the application of "AI + Inspection" in the wire rope sector. By successfully integrating the domestic large-scale model DeepSeek into multiple core scenarios, Luoyang TST Flaw Detection Technology Co., Ltd has significantly improved the efficiency and safety of wire rope inspection.

How Does the Intelligent "AI Doctor" Diagnose Wire Rope Safety?

Leveraging its extensive expertise in the health monitoring of wire ropes and wire rope core conveyor belts, TST has combined the DeepSeek-AI language model to create an AI-powered intelligent safety monitoring solution for the entire lifecycle of wire ropes. This solution deeply integrates intelligent technology into wire rope usage scenarios, bringing innovative breakthroughs to wire rope inspection services.

Breaking Through Tradition: AI Replaces Manual Inspection

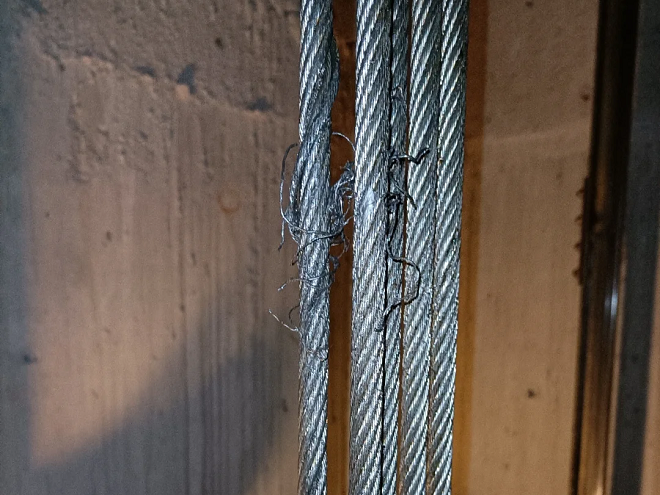

Traditional wire rope inspection primarily relies on visual observation, tactile judgment, and the experience of inspectors to assess wear, broken wires, corrosion, and other damages.

.jpeg)

The internal damage of the wire rope is obscured by grease and dirt

Obvious damage indicates that significant hidden dangers already exist.

However, as industrial technology advances and safety requirements increase, the limitations of manual inspection have become apparent:

1. Insufficient Inspection Depth: Manual inspection can only detect surface damage, making it difficult to identify internal hazards and posing significant safety risks.

2. High Dependence on Personnel: Inspectors need to maintain prolonged concentration, and results are still prone to subjective influences.

3. Low Efficiency: Manual inspection speed is approximately 0.3 meters per second, which is slow and often requires multiple operators, leading to wasted production time and labor costs.

Therefore, the introduction of advanced AI inspection technology has become an inevitable choice for improving efficiency, safety, and reducing costs.

From "Finding a Needle in a Haystack" to "Precision Sniper"

Wire rope damage incidents have always been a major safety hazard in production. TST has trained a safety intelligence system based on the DeepSeek-AI model, increasing the accuracy of wire rope damage identification to 99.99%. The advantages of the intelligent inspection system are evident:

1. Non-Destructive Evaluation: Achieves non-destructive testing, comprehensively, deeply, and accurately inspecting the internal and surface conditions of wire ropes without compromising their physical integrity or performance.

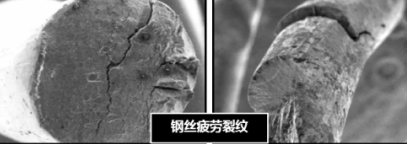

Accurately identify the types of internal and external damage in wire ropes.

2. High Efficiency: Inspection is conducted simultaneously during production, enabling real-time online monitoring and early warning. The system is easy to operate, saving maintenance time and ensuring that even minor damages are detected.

3. High-Precision Identification: AI performs high-precision inspections using a large database to accurately determine the safety status of wire ropes.

4. Intelligent Analysis: Quantitatively detects internal and external damages such as broken wires, wear, corrosion, and fatigue. Combined with the DeepSeek language model, it evaluates the remaining load-bearing capacity and service life of wire ropes with an accuracy rate of up to 99.99%, providing users with scientific basis for safe usage and timely replacement.

Future Outlook

TST has always adhered to technological innovation to drive product upgrades. By integrating the DeepSeek-AI model, the company has further enhanced the intelligence level of its non-destructive wire rope inspection products, achieving digital management of wire rope health throughout their lifecycle. Moving forward, TST will continue to focus on its core business, promoting the transformation of the enterprise through "digital and intelligent" empowerment, and advancing the wire rope safety sector to a higher level.

Through the deep application of AI technology, wire rope inspection has transitioned from traditional manual methods to an intelligent and digital new era, marking a "digital and intelligent leap" in safety production.

prev: With Safety Inspections Lagging Behind, Who Will Protect The Lives of Miners?

next: DeepSeek + Wire Rope Inspection Goes Viral Globally

.jpeg)