Recently, DeepSeek has become a sensation! This China large-scale AI model has not only garnered attention in the AI field but has also demonstrated powerful analytical capabilities across multiple industries. In the critical field of wire rope inspection, high-precision and intelligent technical solutions are equally essential to ensure safety.

Luoyang TST Flaw Detection Technology Co., Ltd. has taken the lead in targeting the "AI + Inspection" application scenario for wire ropes, deeply integrating the domestic large-scale model DeepSeek. By deploying it across multiple core scenarios and leveraging advanced technologies such as deep learning and image recognition, the company has achieved precise identification and prediction of wire rope damage. This will significantly enhance inspection efficiency and accuracy, effectively reducing the occurrence of safety incidents and safeguarding lives and property.

Equipping Wire Ropes with an "AI Brain"

With 38 years of industry expertise and practical experience, TST, as a pioneer in the field of wire rope inspection, has developed a dedicated intelligent wire rope inspection system. This system is non-destructive, real-time, quantitative, qualitative, high-speed, and intelligent—essentially providing an "AI brain" for working wire ropes!

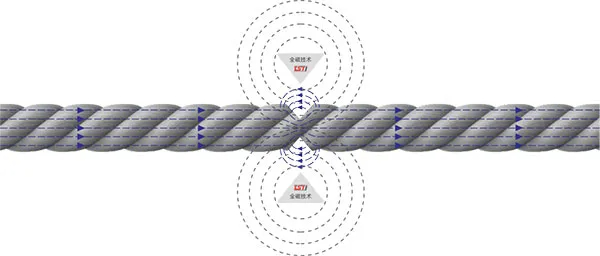

In terms of wire rope safety management and monitoring, TST possesses internationally leading core technology known as "full magnetic flux testing." Its independently developed wire rope safety monitoring system can effectively assess the operational and safety conditions of wire ropes across various industries, enabling data analysis and feedback.

TST's full magnetic flux testing method is a non-contact, non-destructive inspection technique that can examine the entire wire rope without damaging its structure.

▲ Full Magnetic Flux Technology Principle

TST's intelligent non-destructive testing technology, with its outstanding performance and broad application potential, is rapidly emerging as a "high-tech intelligent guardian" in the field of wire rope applications. This technology provides a solid foundation for wire rope safety monitoring, significantly enhancing the reliability of safety production and operational efficiency.

With its "efficient, accurate, and meticulous" inspection capabilities, it has successfully replaced the previously inefficient and high-risk manual inspection methods. It comprehensively captures and precisely locates potential wire rope hazards, ensuring an impregnable safety defense.

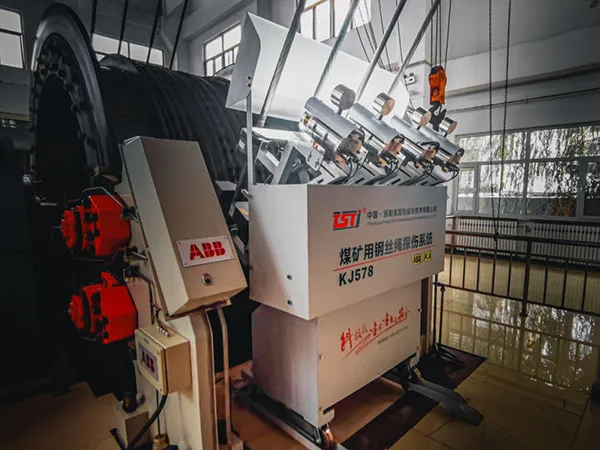

▲ TST Intelligent Wire Rope Inspection System

Inspection: Fast and Efficient

Capable of 365 days * 24 hours real-time online monitoring

Real-time alerts, saving maintenance time

▲ TST Intelligent Wire Rope Inspection System

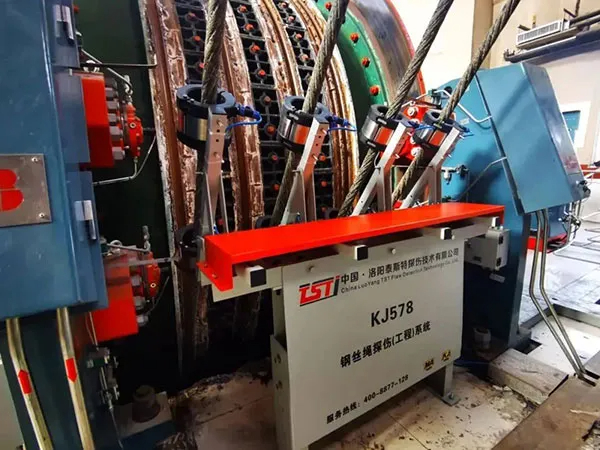

Inspection: Accurate and High Precision

Strictly adheres to national wire rope standards

Evaluates wire rope condition based on inspection results

▲ TST Intelligent Wire Rope Inspection System

Inspection: Precise and Intelligent

Quantitatively detects internal and external damage

Provides scientific basis for assessing service life

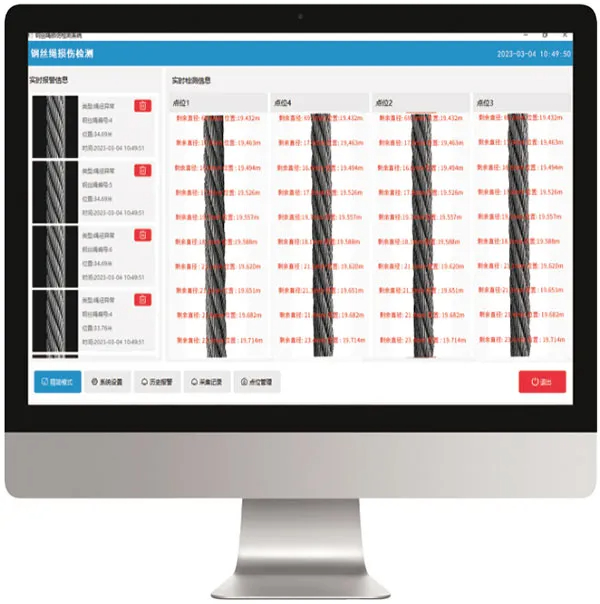

▲ TST AI Visual Image Monitoring System for Wire Ropes

The TST intelligent inspection system, equipped with an advanced AI brain, accurately quantifies and evaluates every internal and external defect in wire ropes, including but not limited to fine broken wires, wear marks, corrosion, fatigue cracks, complex deformations, and strand loosening. Its precision analysis engine monitors the wire rope's condition around the clock without missing a single detail.

Once any abnormality is detected, the TST intelligent inspection system immediately activates a warning mechanism, issuing real-time alerts and automatically generating inspection reports that comply with international safety standards. These reports meticulously document the wire rope's usage history and current condition, providing valuable data support for managers.

More advanced is the system's ability to intelligently predict the future safety trends of wire ropes using deep learning algorithms, as if equipping enterprises with a pair of eyes that can foresee the future for safety production and maintenance management.

The TST intelligent inspection system, driven by AI, not only significantly improves inspection efficiency and accuracy but also builds an indestructible technological defense for the safe use of wire ropes. It is leading the industrial safety inspection field toward a more intelligent and automated future.

prev: DeepSeek Empowers Wire Rope Inspection, Ushering in a "Digital and Intelligent Leap" for Wire Rope Safety Production!

next: Back to List