Recently, engineer from Luoyang TST flaw detection technology Co., Ltd provided professional training and guidance on TST portable wire rope flaw detection system for a mine in Luliang, Shanxi province. This training improved the mine's inspection skills on the TST portable wire rope tester, helped the mining eliminate safety hazards during wire rope operation, and improved the level of safety production management.

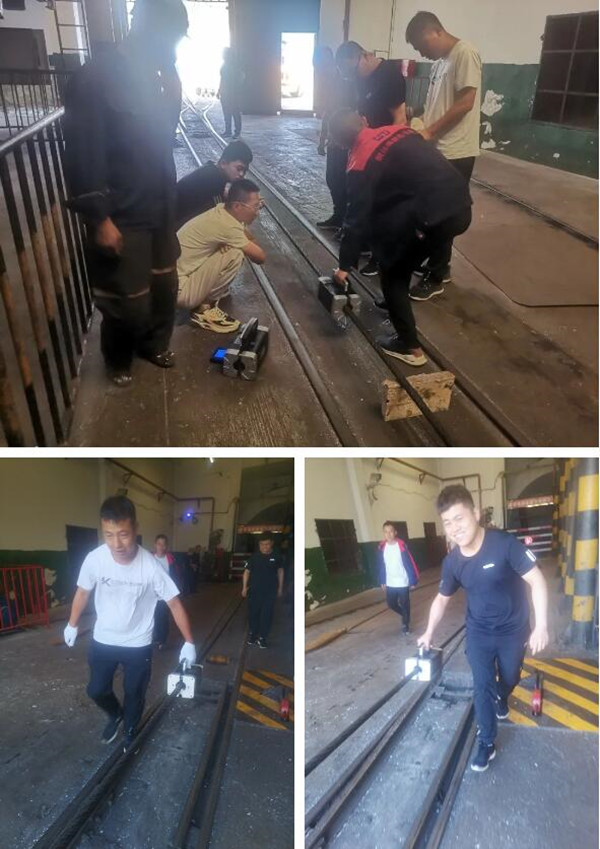

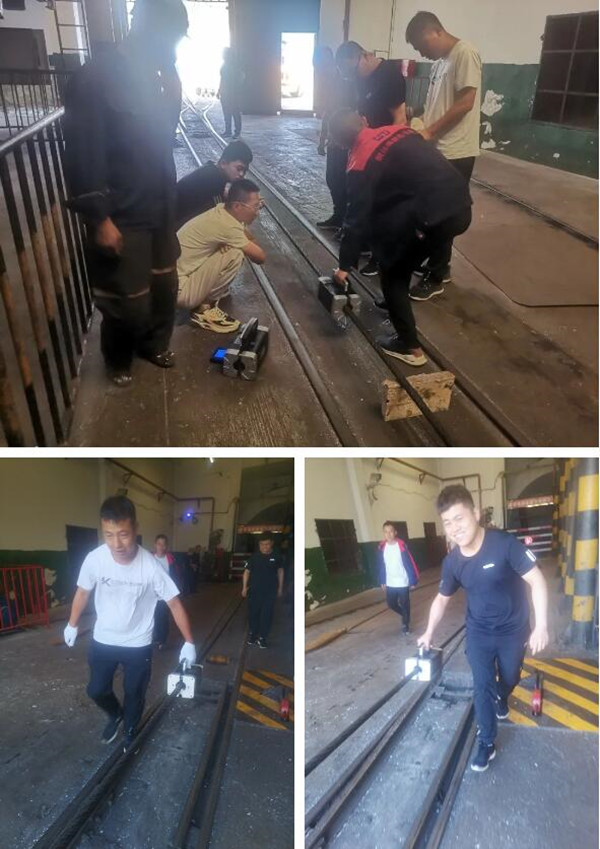

In order to comprehensively ensure the safety operation on the lifting system, a mine in Luliang, Shanxi province recently purchased a TST portable wire rope flaw detection system and put it into use in the production system. Colleagues from Luoyang TST Flaw Detection Technology Co., Ltd. conducted system training for relevant mine workers.

During the training, colleagues from TST first gave a detailed explanation on the components, usage, daily maintenance, product advantages, etc. of the TST portable wire rope tester, focusing on the working principle and detection steps of the system in actual use to ensure the effective operation of the system in daily use.

During the practical operation, TST engineers asked participating customers to operate the device one by one, and provided guidance and answers to existing problems accordingly.

The TST wire rope flaw detection (portable) system adopts the principle of "inductance magnetic flux variable compensation sensor". During detection, it performs identification and analysis based on the magnetic field state inside and outside of the wire rope. It can not only quantitatively detect the inside and outside of the broken wires, rust, wear, etc. on the wire rope, but also the fatigue.

System Features:

1. Quantitative and qualitative: Effectively determine internal and external flaw of the wire rope: broken wires, wear, corrosion, fatigue, kinks, deformation, loose strands, etc.

2. Convenient and fast: small in size, light in weight, easy to inspect, and can be used for regular local flaw detection of consumable and vulnerable parts of the wire rope.

3. High-speed and wide-span: It can finish the inspection at the same time as the production, improving the production efficiency of the enterprise.

4. Strong adaptability: It is suitable for various complex working conditions and is not affected by experience, skills, temperature, speed, noise, water spray, wire warping, oil pollution and other factors.

5. Convenient data processing: it can truly obtain the original flaw information of the wire rope, display the online detection process, and print the detection results in any time.

prev: TST Provides Portable Wire Rope Tester Training to Clients

next: TST attended 2023 China International Coal&Mining Expo.